CARBON RIMS QUALITY

Feb 10, 2020PREPARE MAERIAL:

According to the standard and design structure provided by the developer. Collect, inspect and weigh air bladder and carbon fiber prepregs to verify that all materials are included.The weight must be within to lerance if you want to pass and move on to the next process. The weight and personnel ID# are recorded on the computer to keep the record permanently.

LAYUP:

Each rim uses our carefully designed fixture to make the carbon fiber prepreg layer. Our most experienced workers apply the prepreg by hand, and most of the rim processing process takes 30-45 minutes.

When forming a carbon fiber rim, the temperature and air pressure control process is very important, which determines whether yourproduct has a flawless finish. We use the latest generation of machinery to achieve the most stable temperature and air pressure throughout the heating, curing, and cooling process. Carefully control all aspects during the ~45-minute cycle.

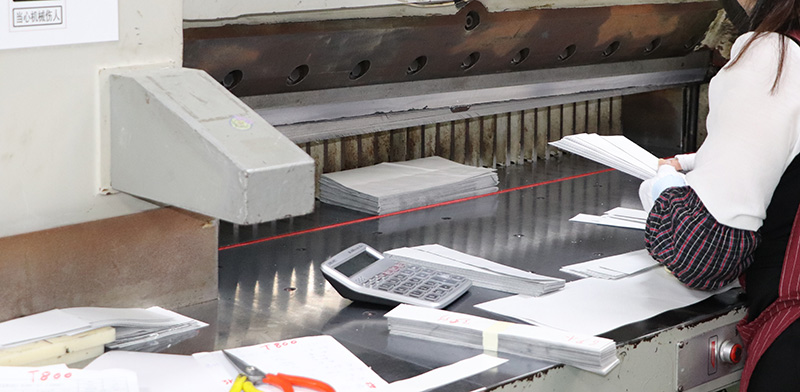

DRILLING:

It is a computer-controlled drilling machine that customizes each spoke hole to an exact position and angle.You can request a customized drilling pattern if you have a unique wheel build. All rims are drilled with a high-speed CNC machine.

This is part of our carbon fiber rim processing, removing the excess resin wicked away during the curing process,and deburring the spoke holes.

We have an independent spray paint production line and strictly control every link, Glossy and Matte finishes,and customized graphics are available.

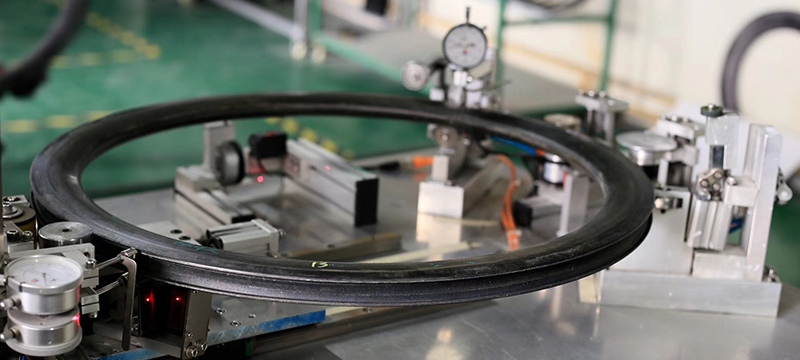

FINAL QC CHECK:

In addition to standard quality control inspections on carbon fiber rims, we also check roundness(must be within 0.2mm), flatness(within 0.15mm), and with some products, the tire pressure check is performed.

All Ornan wheels are lashed and trued by hand. The wheel builder has 10 years of experience and can recognize some issues tools cannot.There are needs at least 4~5 stress relieve rounds during the process.

Final confirmation of customer receipt information. Products are packaged well to avoid damage during transit,and items are cross-referenced by the order, ticket to make sure no parts are missing.

SHIPPING:

We have several options for shipping depending on your location. We partner with EMS, DHL, TPD (Tax Prepaid),Fedex, and TNT.

* For more information about carbon wheels, carbon rims: click here...

Carbon wheels: 29er/650B MTB Wheels, 700C/650B Gravel Wheels, 700C Road Disc Brake, 700C Road Rim Brake, TT/Track wheels, 700C UD carbon spokes, Folding Spoke wheels.

Carbon rims: 700C road rims, 29er/650B MTB rims, 700C/650B gravel rims, BMX rims.